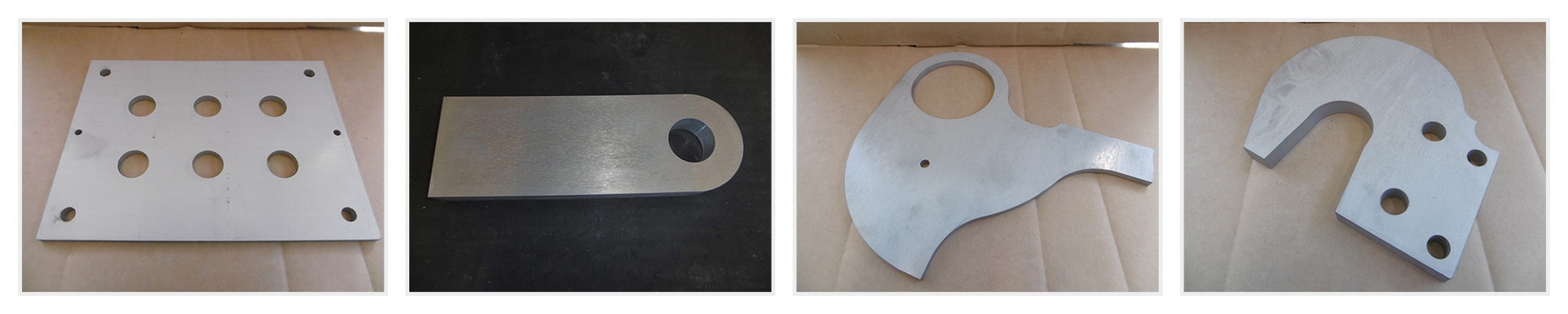

Waterjet Cutting

Phoenix Hydraulics provides the most versatile and high-precision process for shape-cutting.

Waterjet cutting utilises an ultra-high-pressure stream of water to carry an abrasive grit. To create a smooth finish, the abrasive carries out the cutting process using a sawing action.

The very exact cutting process is suitable for almost any type of material, with the narrow kerf width permitting fine contours to be cut to create high-tolerance parts. The process employs an intensifier pump to create the ultra-high water pressure (up to 90,000 psi) that is required for cutting hard materials.

The electro-servo pump is a revolutionary concept in waterjet cutting. Directly enveloping a high-load precision ball screw that houses ceramic plungers, they reciprocate backwards and forwards to create a pumping action - in a similar way to the hydraulic cylinder in an intensifier waterjet pump.

When combined with the infinite control of the servo motor, the precision of the ball screw enables extremely accurate control over the volume of water displaced and the output pressure, thus eliminating pressure spikes when deadheading.

The operator has the ability to programme virtually any pressure and flow rate, while using only the power displaced at the cutting head.

Compared with traditional profiling methods, there are many advantages to using waterjet cutting technology. Virtually any material can be cut, from 1mm to 40mm thickness. There's no heat in the process, so there is no distortion of the material. Clean and highly accurate cuts reduce the need for additional machining.

Waterjet cutting is commonly used for fabricating machine parts and is the preferred process when materials are likely to be affected by the high temperatures required by other methods. It is used in various industries, including mining and aerospace - it has been the preferred solution in the aerospace industry since the 1970s.

Please contact us to discuss your waterjet requirements - we have a maximum cutting area of 1.5m x 3m. We also have a full CNC machine shop, so we can cater to any additional machining to provide a finished product.