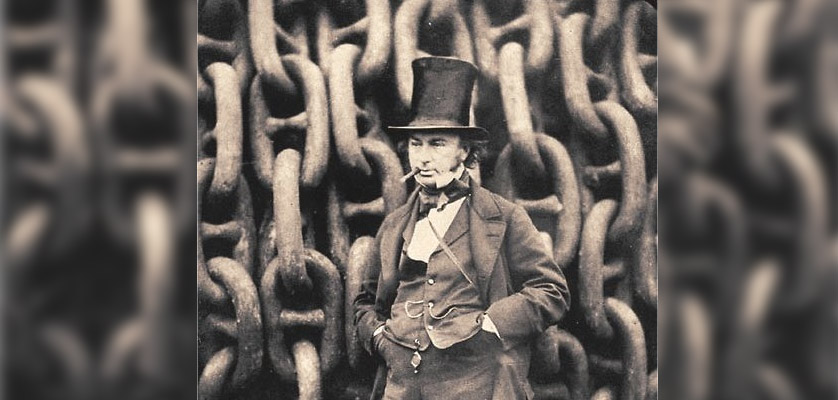

Isambard Kingdom Brunel: SS Great Britain

Isambard Kingdom Brunel was one of England's greatest mechanical and civil engineers of all time. The Portsmouth-born engineer was responsible for designing and constructing some of the greatest bridges of the 19th century, using innovative techniques that had never before been seen.

Born on 9th April 1806, he was the son of Sir Marc Isambard Brunel, who was a highly successful French civil engineer, who moved to the UK as a result of his work. Isambard was already a child prodigy by the age of four, as his father taught him some of the skills essential to civil engineering, including observational and drawing techniques.

The youngster was sent to the top schools in France and England and by the age of eight, he had already learned basic engineering principles, such as Euclidean geometry - a specific mathematical system with its origins in Ancient Greece.

Credit: Wikipedia

Prodigy's first jobs

One of Isambard's first jobs was working on the construction of the Thames Tunnel under the River Thames with his father. He also designed the famous Clifton Suspension Bridge in Bristol, which towered more than 240ft above the River Avon. Construction began in 1831 and it was the world's longest bridge at the time.

Another of his successful projects was the unique Royal Albert Bridge in the mid-19th century. Even today, it remains a miracle of engineering, standing 100ft tall and spanning the 1,100ft-wide River Tamar.

A popularity poll in the 21st century placed the engineer as the second best Brit in history, behind only our wartime Prime Minister, Sir Winston Churchill.

Brunel was undoubtedly Britain's top engineer of the 19th century and one of his greatest achievements was the SS Great Britain - an iron steamship that was one of the largest vessels in the world.

Ship's construction

Manufactured from wrought iron, the SS Great Britain was constructed in Bristol in 1843. Brunel supervised the building process for the Great Western Steamship Company. The vessel set the standard for today's modern ships and was a prime example of the innovations of the 19th century and of Brunel in particular.

His ideas shaped the future of passenger travel and international communication almost single-handedly. The construction process was a masterpiece of civil engineering.

The SS Great Britain was originally designed to be a paddle steamer, but the concept was altered when the new technology of screw propulsion came into being. The ship's engines were converted so they would power the 16ft wrought iron propeller.

She was by far the biggest ship in the world, measuring almost 100 metres long - more than 30 metres bigger than her nearest rival. In addition, she was the first wrought iron ocean-going ship that was screw propelled.

She weighed a gigantic 1,930 tons and was designed to capitalise on the new Trans-Atlantic luxury passenger business. Capable of carrying 252 passengers in first and second-class berths, plus the 130-strong crew, the ship had many luxurious rooms.

Gold rush transporter

The ship's technological abilities became apparent as soon as she went into service. Sadly, her career as a passenger liner was short lived after the captain inadvertently ran her aground in 1846, on the beaches of Dundrum Bay in Northern Ireland. When it was found her engines were significantly damaged, the Great Western Steamship Company sold her, fearful of the expense of the repairs.

She was purchased by Gibbs Bright and Co and subsequently prospered. In the interim, the famous Australian gold rush had begun, and prospectors were travelling from far and wide in a bid to strike gold. The ship's new owner capitalised on the increasing numbers of people wishing to emigrate and the SS Great Britain was rebuilt to carry people to Australia.

This involved adding a new upper deck and fitting a new engine. Her capacity was increased to carry 750 passengers in three classes of accommodation. The ship continued transporting people to Australia for 24 years and carried an estimated 16,000 passengers in that time.

She became known as the "greyhound of the seas" due to the smooth and fast passage that she provided. The return journey took 120 days, which sounds slow by today's standards, but this was very competitive in the 19th century. Passengers were almost guaranteed to arrive on time and the sail-powered ships couldn't compete with her modern prowess.

Warship

The ship has a fascinating history. In 1854, she was chartered by the British government to carry soldiers to and from the Crimean war. She carried more than 44,000 troops during the conflict. Following another rebuild, she was then commandeered by the government a second time to carry the 8th Hussars and the 17th Lancers to try and quell the Indian mutiny.

The SS Great Britain had a rather more pleasurable task following the rigours of war. In 1861, the first ever England cricket team was transported to Australia in the famous ship. A crowd of 15,000 went to the first match in Melbourne and the tour was a huge success, with England playing 12 games in total, of which they won six, drew four and lost two.

In the late 1870s, the ship's engines were becoming worn and so they were removed. She was then converted into a sailing ship with three masts. She began transporting coal from Wales to San Francisco but suffered problems at Cape Horn and had to take shelter in the Falkland Islands at Port Stanley. As a result, she was damaged and sold on as a storage space for coal and wool, remaining stationary in Port Stanley.

20th century

She remained in Port Stanley through the First World War, when coal stored on the mighty vessel was used to power the battleships, Invincible and Inflexible. In 1937, it was noted that the mighty hull was not watertight. She was beached and abandoned after being towed away from Port Stanley.

A number of attempts to salvage her were unsuccessful, including one in the 1960s. However, in 1970, a major salvage effort was launched and the ship was finally refloated and towed back across the Atlantic to Bristol.

Even though she had been exposed to the Atlantic conditions for decades, she was still able to sail up the River Avon unaided! The ship had covered more than one million miles during her working life and her old iron hull, designed by Brunel, had stood the test of time for more than 100 years.

Another refurbishment was carried out at a cost of £11.3 million and SS Great Britain was re-launched as a world-famous maritime museum in 2005.

Shot blasting

The process of shot blasting is still used in the shipbuilding industry today. The process is crucial to remove mill scale - a brittle layer of iron oxide that can detrimentally affect the steel plate. The mill scale is removed from the plate's surface by shot blasting, as it can contaminate the weld, reducing its quality.

Shot blasting involves passing the plate through an enclosed chamber and blasting it with steel shots at very high velocity. Each shot will scrape away the mill scale. The size, mass and velocity of the shots are pre-determined to make sure that the mill scale is totally removed.

Please contact Phoenix Hydraulics on 01733 234800 for information on our professional shot blasting services for maritime and other applications.